What Are the Uses of a Loading Dock Table?

What Are the Uses of a Loading Dock Table?

Loading dock tables are modern equipment designed to ensure the safe and efficient transportation of heavy loads. In this blog post, we will explore the applications, industry preferences, and advantages of loading dock tables in detail.

What Is a Loading Dock Table and What Are Its Purposes?

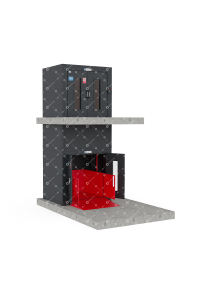

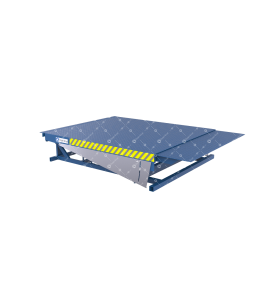

Loading dock tables are platforms equipped with a hydraulic mechanism that facilitates lifting and transporting heavy loads.

Main purposes include:

- Heavy load handling: Capable of lifting loads ranging from 500 kg to 20,000 kg.

- Leveling height differences: Bridges height gaps between vehicles and the ground, particularly during loading and unloading.

- Safe transportation: Features such as safety frames and overload protection systems ensure a high level of safety.

Which Industries Prefer Loading Dock Tables?

Thanks to their wide range of applications, loading dock tables are frequently used in various industries:

- Logistics and Warehousing: Used for transporting and organizing materials in storage areas.

- Manufacturing and Factories: Play a critical role in moving raw materials and products to production lines.

- Retail and Distribution: Facilitate the movement of goods in large shopping malls and distribution centers.

- Construction Industry: Ideal for safely transporting and placing heavy construction materials.

What Types of Loads Can Be Transported with a Loading Dock Table?

Loading dock tables are specifically designed to handle different types of loads:

- Palletized goods: Commonly used in logistics and storage sectors.

- Heavy industrial products: Such as steel, concrete, and other heavy materials.

- Delicate equipment: Including electronic devices and fragile items.

When Does Using a Loading Dock Table Offer Advantages?

The use of loading dock tables provides numerous advantages:

- High capacity: Offers a load capacity of up to 20 tons, making it ideal for heavy-duty operations.

- User-friendly design: Equipped with a 24V DC control unit for easy and safe operation.

- Low maintenance cost: High-quality hydraulic cylinders and maintenance-free rollers ensure long-lasting use.

How Does Using a Loading Dock Table Impact Work Efficiency?

- Operational speed: Facilitates the quick transport of heavy loads, accelerating production and logistics processes.

- Labor savings: Requires less manpower compared to manual handling methods.

- Reduced error risks: Stability and safety features minimize workplace accidents.

Comparison of Loading Dock Tables with Alternative Methods

Loading dock tables offer several advantages over alternative methods:

- Compared to forklifts: Provide a wider load capacity and easier height adjustment.

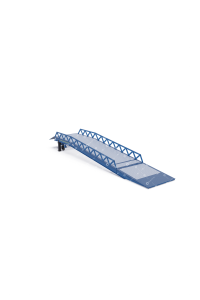

- Compared to ramp systems: Offer a more compact solution and greater safety during transportation.

Key Considerations for Using a Loading Dock Table

- Certification check: Models compliant with the EN 1570-1 European Standard should be preferred.

- Regular maintenance: Ensure routine checks of components such as hose burst valves and roller bearings.

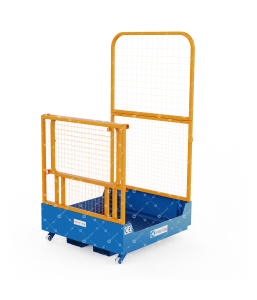

- Accessory selection: Enhance safety with accessories like rotary tables, bellows, and guardrails.

Conclusion

Loading dock tables are critical equipment that enhances both safety and efficiency in work processes. Choosing the right platform not only meets your business needs but also provides long-term cost advantages. Önder Lift offers customer-focused production and a wide range of products to provide the best solutions for your loading dock table needs. For more information, contact our expert team today.

Categories

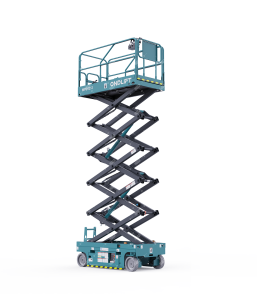

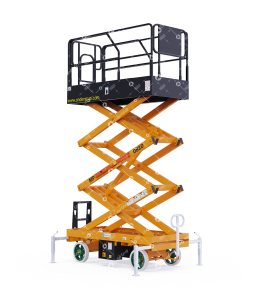

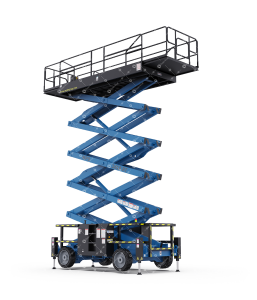

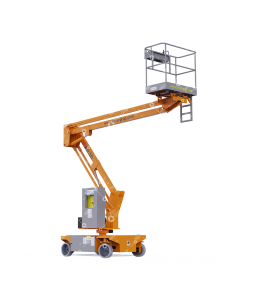

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

Onderlift is Taking Its Place at ProMat 2025!

What to Consider When Choosing a Mobile Scissor Lift Table?

What Is a Mobile Scissor Lift Table and Where Is It Used?

What to Consider When Choosing a Loading Dock Table?