Advantages of Using a Tilt Table for Heavy Load Handling

Advantages of Using a Tilt Table for Heavy Load Handling

In heavy load handling processes, safety, efficiency, and ergonomics are top priorities. Tilt tables fulfill these priorities by accelerating workflows and enhancing worker safety. In this blog post, we delve into the benefits, types, and key considerations for selecting the right tilt table.

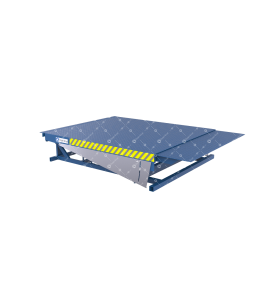

What is a Tilt Table, and Why is it Preferred for Heavy Load Handling?

Tilt tables are equipment designed to provide ergonomic loading and unloading by tilting loads at specific angles. Operating on hydraulic principles, these tables enable the secure and efficient handling of heavy loads.

Why Choose a Tilt Table?

- Ergonomics: Reduces physical strain on workers, lowering the risk of workplace injuries.

- Safety: Offers safety features like anti-crush systems and overload protection despite high load capacities.

- Efficiency: Speeds up workflows, reducing operational costs.

Types of Tilt Tables for Heavy Load Handling

Various tilt table types are developed to meet different operational needs. Below are the most common types and their applications:

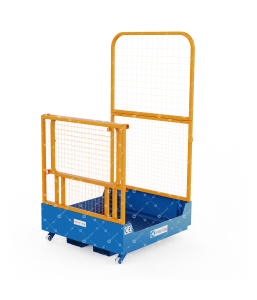

When to Use a Lift and Tilt Table?

Lift and tilt tables are ideal for tight spaces and height-specific requirements.

Applications:

- Transporting heavy loads in warehouses

- Moving materials to production lines in factories

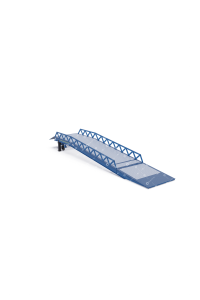

What is a Low Profile Armlift, and What Are Its Advantages?

Low profile armlifts are preferred for areas with minimal height requirements.

Advantages:

- Requires less space

- Easy to install

- Low energy consumption

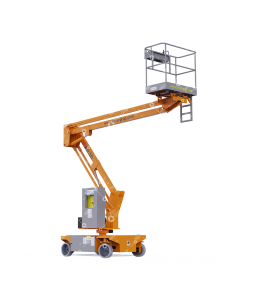

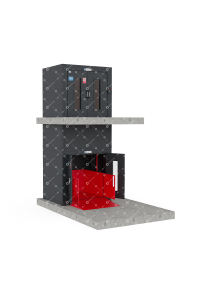

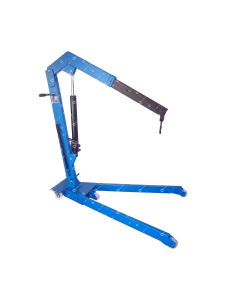

How Does an Armlift Differ from Other Platforms?

Armlifts offer a wide tilting angle (up to 90°), making them suitable for handling large and heavy loads. They are particularly favored in sectors requiring high capacities.

Benefits of Tilt Tables in Heavy Load Handling

Tilt tables provide significant advantages in terms of both workplace safety and operational efficiency.

How Do They Improve Work Efficiency?

- Accelerate loading and unloading processes

- Minimize operational disruptions

- Enable more work with fewer employees

What Are Their Safety Benefits?

- Prevent accidents with anti-crush systems

- Ensure safe operation with overload protection features

- Comply with international safety standards with CE certification

How Do They Reduce Operational Costs?

- Durable hydraulic systems lower maintenance costs

- Energy-efficient motors reduce operating expenses

How to Choose the Right Tilt Table?

Selecting the right tilt table is critical for ensuring operational efficiency and safety. Here are key factors to consider during the selection process:

How to Choose a Tilt Table Based on Load Capacity?

The platform’s load capacity should match the weight of the loads being handled. For instance:

- 100 kg – 1 ton: Suitable for small-scale operations

- 1 ton – 150 tons: Ideal for industrial and heavy-duty applications

What Types of Platforms Are Suitable for Specific Applications?

- Lift and Tilt Table: For tight spaces requiring high load capacities

- Low Profile Armlift: For compact spaces with low height requirements

- Armlift: For handling large, heavy loads with a wide tilt angle

What to Consider for Long-Term Use?

- Regular maintenance: Check hydraulic fluids and test anti-crush systems

- Choosing the right accessories: Additional features like rotary tables, bellows, or photoelectric control systems can extend the product’s lifespan

Conclusion

Tilt tables are among the most effective solutions for ensuring safety and efficiency in heavy load handling processes. Choosing the right type of tilt table optimizes workflows and enhances employee safety.

At Önder Lift, we provide tilt table models tailored to your business needs. Contact us for more information.

Categories

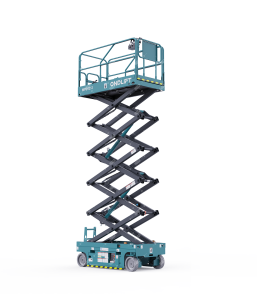

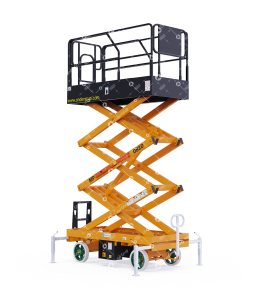

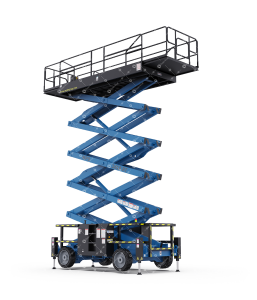

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

Advantages of Using a Tilt Table for Heavy Load Handling

What Are the Benefits and Applications of Tilting Platforms?

What Are the Types of Load Platform Accessories?

The Most Useful Accessories for Load Platforms and Selection Guide

How Can You Improve Workplace Safety with Load Platform Accessories?