Proper Installation and Maintenance Steps for Load Platforms

Proper Installation and Maintenance Steps for Load Platforms

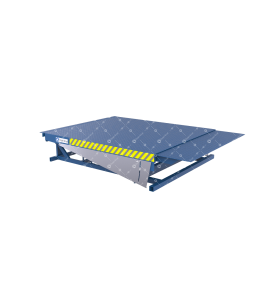

Load platforms are essential equipment that facilitates load handling operations in industrial enterprises and increases operational efficiency. However, for these systems to work safely and last longer, proper installation and regular maintenance steps must be followed. In this article, we will cover the important aspects of load platform installation, how to make hydraulic connections, and maintenance tips that will ensure the long life of the platforms.

Key Considerations for Load Platform Installation

Proper installation of load platforms is critical to ensure safe and efficient operation. The following steps should be taken into consideration during installation:

- Ground Preparation and Stability: The load platform must be mounted on a flat and stable ground. The floor must be solid enough to support the platform’s weight and movements, with no tilting or sinking. It must be ensured that the base frame of the platform is fully compatible with the ground, and reinforcement should be done if necessary.

- Installation Clearances: Adequate clearance should be left around the platform during installation. To allow the platform to move freely during operation, a minimum of 2.5 cm space should be left around the platform.

- Mounting Fastening: The platform must be securely fastened to the ground or wall. Suitable size anchor bolts should be used for this, and bolts should be mounted in accordance with local codes and safety regulations. Care must be taken to ensure that the bolts do not pass through concrete cracks or expansion joints during installation.

- Hydraulic and Electrical Connections: During installation, the hydraulic and electrical connections of the platform must be made by qualified personnel. It should be ensured that the hydraulic system lines are clean and connected correctly, and the electrical connections must be made with the correct voltage.

How to Make Hydraulic Connections?

The hydraulic system, one of the most important components of load platforms, controls the lifting and lowering operations. Improper hydraulic connections can cause the system to fail or result in serious malfunctions. Therefore, the following points should be considered when making hydraulic connections:

- Cleaning of Hydraulic Lines: Hydraulic lines must be cleaned with compressed air before connecting. This ensures that any dust, dirt, or metal particles accumulated inside the lines are cleaned and prevents them from damaging the system.

- Quality of Hydraulic Oil: The hydraulic oil used must be clean and of the correct viscosity. The recommended hydraulic oil is ISO 46 standard oil, and no other oil should be used. It is important to regularly check and replace the oil to maintain the performance of the hydraulic system.

- Inspection of Hydraulic Connections: It should be ensured that the hydraulic connections are tight. Additionally, care should be taken to ensure that the hydraulic lines do not touch the moving parts of the platform. The hydraulic lines should be installed with a certain amount of flexibility to prevent pinching or damage as the platform moves.

Maintenance Tips for Prolonging the Life of Load Platforms

Regular maintenance is required for load platforms to operate without problems for a long time. The basic steps that should be followed during maintenance are as follows:

- Daily Inspections: It is recommended that the platform be visually inspected before each daily use. It is important to check the oil level, ensure there are no leaks, and verify that the electrical cables are intact.

- Monthly Maintenance: The mechanical and hydraulic components of the platform should be inspected in detail on a monthly basis. Hydraulic cylinders, hoses, and connection points should be checked for wear and leaks. The color and consistency of the oil should be inspected, and it should be replaced if necessary.

- Annual Maintenance: All hydraulic oil in the platform should be replaced annually. In addition, filters should be renewed, and the structural integrity of the platform should be inspected. The electrical system should be checked for proper operation, and any signs of wear or loosening should be addressed.

- Safety Measures: During maintenance, the platform should be secured to ensure the safety of the personnel working beneath it. The platform should be stabilized using maintenance rods, preventing it from falling unexpectedly and ensuring workplace safety.

By following these steps, you can ensure that your load platforms operate safely and last longer. Proper installation and regular maintenance not only increase equipment efficiency but also prevent potential accidents.

Categories

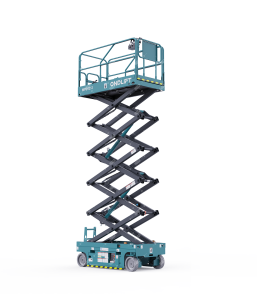

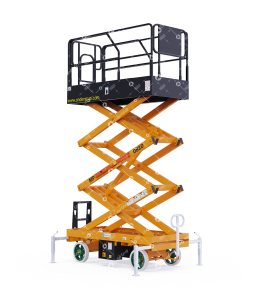

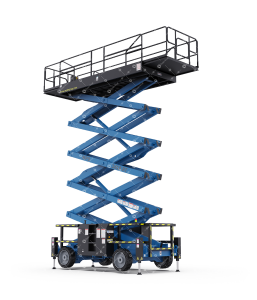

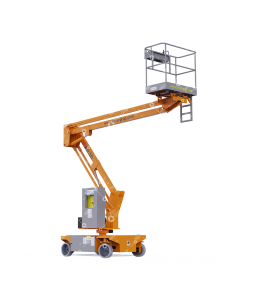

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

Key Considerations When Choosing a Tandem Type Scissor Lift

What is a Tandem Type Scissor Lift?

Advantages of Using a Tilt Table for Heavy Load Handling

What Are the Benefits and Applications of Tilting Platforms?

What Are the Types of Load Platform Accessories?