Safe Usage Procedures for Load Platforms

Safe Usage Procedures for Load Platforms

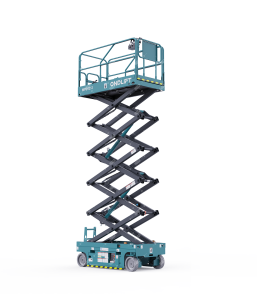

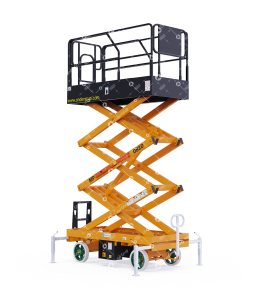

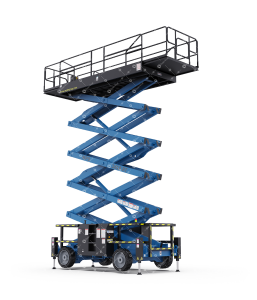

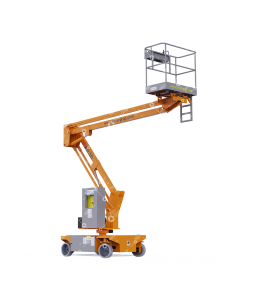

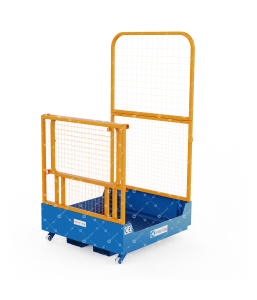

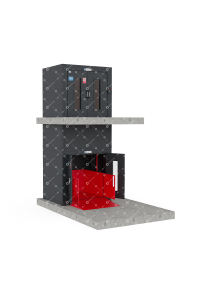

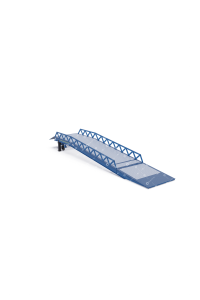

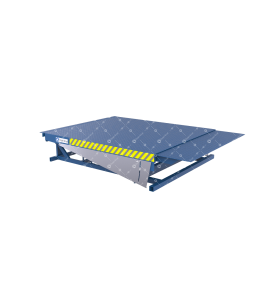

Load platforms are frequently used equipment in industrial settings to transport and lift heavy loads. However, for these platforms to be used safely, operators must follow specific safety rules and work carefully. In this article, we will examine the key safety signals, warning symbols, and the emergency stop button, all of which are critical to the safe operation of load platforms.

Load Platform Safety: Which Signals and Symbols Are Crucial?

Load platforms are equipped with various safety signals and symbols to ensure a safe working environment. These symbols warn users of potential dangers and ensure safe operating conditions. Here are the key signals to watch out for:

- Danger Warning Symbols: These red and yellow symbols alert operators to dangers such as moving parts or crush hazards. These symbols may appear around the platform or on the control panel and must be carefully followed to prevent serious accidents.

- Load Capacity Warnings: Load platforms are designed to handle specific weight capacities. Capacity signs indicate the safe limits of the platform and prevent overloading.

- Hydraulic Oil Level Indicators: For hydraulic systems to function properly, oil levels must be within the recommended range. These indicators warn operators if oil levels drop and ensure the platform operates safely.

5 Essential Safety Rules When Using Load Platforms

There are certain basic rules that must be followed when using load platforms:

- Trained Operator Use: Operators who use load platforms must receive proper training and fully understand the system. Trained operators can safely use the platform and prevent potential errors.

- Respect the Load Capacity: The platform’s capacity should never be exceeded. Overloading can cause the platform to become unstable or lead to system malfunctions.

- Load Only When the Platform is Stationary: Always load and unload the platform when it is stationary. Handling loads while the platform is moving can lead to serious accidents.

- Daily Visual Inspections: Critical components such as hydraulic hoses, control panels, and safety mechanisms should be inspected daily. This ensures that any potential issues are identified and addressed promptly.

- Use Safety Equipment: Safety shields, barriers, and stabilizer rods must be used on load platforms. These devices enhance the platform’s safety and protect operators from harm.

What is the Emergency Stop Button on a Load Platform, and How is it Used?

The emergency stop button on load platforms ensures that the system is stopped immediately in case of an emergency. This button deactivates the platform instantly, preventing potential accidents.

- Using the Emergency Stop Button: If a danger arises while the load platform is in use (e.g., a crush hazard, malfunction, or loss of control), the emergency stop button should be pressed. This halts the platform immediately, preventing accidents.

- Strategic Placement of the Button: The emergency stop button is typically located on the control panel and should be easily accessible. Operators must know where this button is and be able to reach it quickly if needed.

- What to Do After Pressing the Button?: After pressing the emergency stop button, a technical inspection must be performed before the platform is restarted. The system should not be restarted until any detected issues have been resolved.

Daily Inspections to Conduct Before Using a Load Platform

Daily inspections ensure that the platform operates safely and help prevent potential breakdowns. Before using the load platform, the following checks are recommended:

- Hydraulic Hoses: Check for any leaks.

- Electrical Cables: Ensure there are no loose or damaged cables.

- Load Capacity: Ensure you are not exceeding the platform’s capacity.

- Visual Inspection: Examine the platform for any physical damage or wear.

Why Is Load Platform Safety So Crucial?

Because load platforms are used to lift heavy loads to high places, safety is paramount. A malfunction or improper use can result in serious injuries and financial losses. Properly applying safety measures protects both operators and the work environment.

Following safety procedures for load platforms is essential to preventing accidents and extending the life of the equipment. Paying attention to safety signals and warning symbols, conducting daily inspections, and using the emergency stop button when necessary will ensure a safe and efficient working environment. Remember, safety should always be your top priority!

Categories

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

What to Consider When Choosing a Loading Dock Table?

What Are the Uses of a Loading Dock Table?

Key Considerations When Choosing a Tandem Type Scissor Lift

What is a Tandem Type Scissor Lift?

Advantages of Using a Tilt Table for Heavy Load Handling