What Are the Uses and Benefits of Hydraulic Presses in Industry?

What Are the Uses and Benefits of Hydraulic Presses in Industry?

Hydraulic presses are one of the most important machines in modern industry. By applying high pressure, they facilitate processes such as metal forming, cutting, bending, and compressing. In this article, we will examine in detail the areas of use, benefits, and differences between hydraulic and manual presses in industry.

What is a Hydraulic Press? How Does It Work?

A hydraulic press operates based on Pascal’s Law. This machine generates large forces using liquid pressure. By passing pressurized fluid through a cylinder, the pressing process is performed. The high precision and strong compression capacity make hydraulic presses indispensable in industry.

Basic Working Principle of Hydraulic Presses

- Pascal’s Law: The pressure applied by the hydraulic fluid is transmitted equally in all directions.

- Pressure Application: The pressure created by a small-diameter cylinder generates high force in a larger-diameter cylinder.

- Control: Pressure and force can be controlled precisely during the process.

Where Are Hydraulic Presses Used in Industry?

Hydraulic presses have a wide range of applications and are widely preferred in various industrial sectors. Here are the most common areas where hydraulic presses are used:

- Automotive Industry: Used in metal forming and cutting processes for part production.

- Aviation Industry: Hydraulic presses are preferred in the production of aircraft parts requiring high precision.

- Construction Industry: Used in shaping and cutting steel and metal building materials.

- Plastics and Rubber Industry: Hydraulic presses are used in the molding and pressing processes of plastic and rubber parts.

What Are the Advantages and Disadvantages of Hydraulic Presses?

Hydraulic presses offer many advantages, but there are also some disadvantages.

Advantages of Hydraulic Presses

- High Power: Hydraulic presses provide high pressure and force with low energy.

- Precision: The ability to precisely control the force applied during processes provides a significant advantage, especially in sectors requiring fine craftsmanship.

- Less Component Wear: Despite operating under high pressure, hydraulic presses have a lower rate of mechanical wear.

Disadvantages of Hydraulic Presses

- Maintenance Requirement: Situations such as fluid leaks require regular maintenance.

- High Initial Cost: Compared to other types of presses, the initial cost is higher.

Differences Between Manual and Hydraulic Presses

Manual presses are also frequently used in industrial environments, but there are some fundamental differences between them and hydraulic presses:

- Manual Presses: Operated by human power and are generally ideal for smaller-scale processes and lower costs. Preferred in low-volume production.

- Hydraulic Presses: Ideal for processes requiring higher force and pressure. More efficient in large-scale and continuous production. They are also used for precision work and processing larger parts.

How to Maintain Hydraulic Presses?

Regular maintenance of hydraulic presses extends the machine’s lifespan and improves efficiency. Here are some maintenance tips to keep in mind:

- Regular Fluid Check: The level and quality of the fluid used in the hydraulic system should be checked regularly.

- Leak Detection: Fluid leaks are one of the most common issues in hydraulic systems. Therefore, regular leak checks should be carried out.

- Cleaning: Regular cleaning of hydraulic presses and protection against environmental contamination ensure their longevity.

- Proper Usage: Training operators and using machines correctly will extend equipment life.

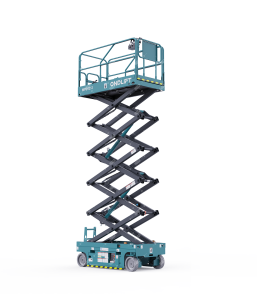

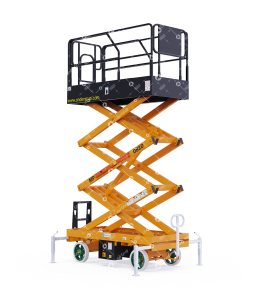

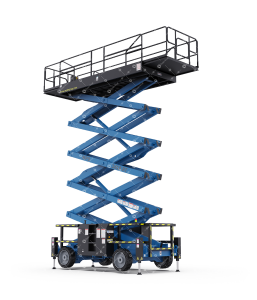

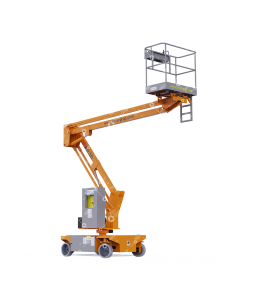

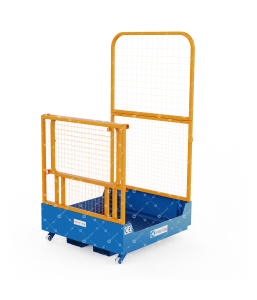

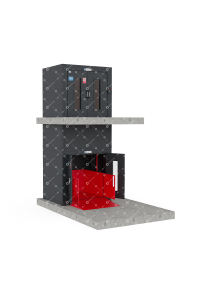

What is the Importance of Hydraulic Platforms in Industry?

In addition to hydraulic presses, hydraulic platforms play an important role in industrial processes. They are widely used in lifting, transportation, and assembly operations.

Uses of Hydraulic Platforms in Industry

- Construction and Assembly Work: Used to safely transport heavy loads to high places.

- Storage and Logistics: Preferred in warehouse arrangements that require height adjustment.

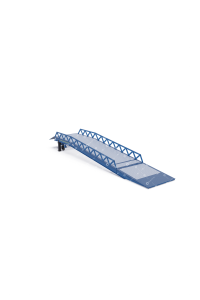

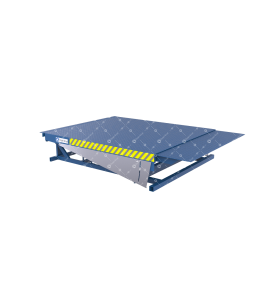

- Loading and Unloading: Hydraulic platforms provide great convenience in loading and unloading processes of transport vehicles such as trucks.

Hydraulic presses are essential tools that provide high efficiency and precision in many different sectors of industry. They reduce labor while increasing production speed and allow for the easy processing of heavy loads. Manual presses are suitable for smaller, lower-cost jobs, while hydraulic presses are indispensable in large-scale production. At Önder Lift, we are proud to offer the most suitable hydraulic press and platform solutions to meet your industrial needs. For more information, please contact us.

Categories

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

Onderlift is Taking Its Place at ProMat 2025!

What to Consider When Choosing a Mobile Scissor Lift Table?

What Is a Mobile Scissor Lift Table and Where Is It Used?

What to Consider When Choosing a Loading Dock Table?