What to Consider When Choosing a Loading Dock Table?

What to Consider When Choosing a Loading Dock Table?

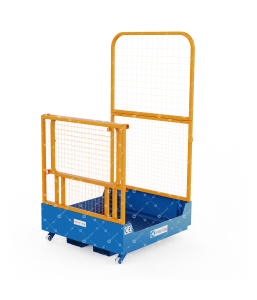

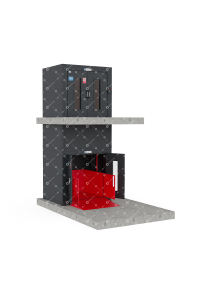

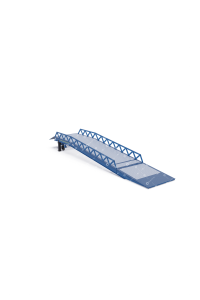

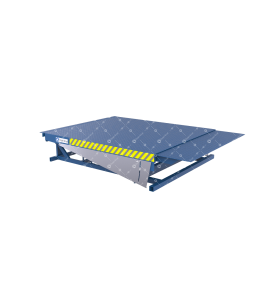

Loading dock tables are critical equipment designed to ensure the safe and efficient transportation of heavy loads. Choosing the right platform is essential for the smooth execution of operations and reducing long-term costs. In this article, we will explore the key criteria to consider when selecting a loading dock table.

What Is a Loading Dock Table and Why Is It Important?

Loading dock tables are platforms equipped with hydraulic mechanisms, used for lifting, transporting, and elevating heavy loads. These platforms not only enhance efficiency but also ensure workplace safety. Customizable to specific measurements, they offer flexibility to meet the needs of various industries.

Are Capacity and Size Important When Choosing a Loading Dock Table?

Loading dock tables come with lifting capacities ranging from 500 kg to 20,000 kg. It is crucial to consider the weight of the loads you intend to handle when making a selection. Insufficient capacity can lead to safety risks, while an excessively high capacity can increase costs unnecessarily.

The physical dimensions of the platform should match your workspace. Its height, width, and table size should be tailored to your storage area and operational needs.

How to Choose the Right Platform Based on Its Purpose?

Loading dock tables cater to various needs across different industries. Consider your purpose when making a selection:

- Logistics and Warehousing: Ideal for moving palletized loads. Compact models are preferable for tight spaces.

- Construction and Industry: High-capacity platforms are required for transporting heavy construction materials.

- Production Lines: Platforms with features like anti-crush systems are suitable for handling delicate equipment.

What Safety Features Should a Loading Dock Table Have?

The safety features of a platform are critical for both operator security and the longevity of the equipment. Look for platforms with the following features:

- EN 1570-1 European Standard: CE-certified products meet international safety standards.

- Safety Frame: Anti-crush mechanisms prevent workplace accidents.

- Overload Protection System: Prevents overloading beyond the platform’s capacity.

- Hose Burst Valves: Provides safety in hydraulic systems.

What Factors Determine the Durability and Maintenance of a Loading Dock Table?

The durability and ease of maintenance of a loading dock table depend on the materials and technologies used:

- Material Quality: Reinforced hydraulic hoses and high-quality cylinders ensure long-term use.

- Ease of Maintenance: Maintenance-free roller bearings and safety bars provide cost-effective usage.

- Testing Procedures: All platforms should be tested with loads exceeding their capacity by 30%.

The Importance of Technical Support and Warranty When Purchasing a Loading Dock Table

Key factors to consider during the purchase process:

- Technical Support: Opt for a reliable brand that provides after-sales support and spare parts availability.

- Warranty Period: A long warranty indicates confidence in the product’s durability and helps reduce operational costs.

Common Mistakes When Buying a Loading Dock Table

Avoid the following common mistakes during the selection process:

- Underestimating Capacity Requirements: Selecting a platform with insufficient capacity can lead to safety risks.

- Ignoring Safety Certifications: Products lacking CE certification and other standard documents may increase costs in the long run.

- Overlooking After-Sales Support: The absence of technical support and spare parts providers can disrupt workflows.

Conclusion

Choosing the right loading dock table is a crucial step that directly impacts the efficiency and safety of your operations. By considering criteria such as capacity, size, safety features, and durability, you can make the best selection for your needs. Önder Lift helps optimize your workflows with safe and durable loading dock tables tailored to your requirements. Contact our expert team for more information.

Categories

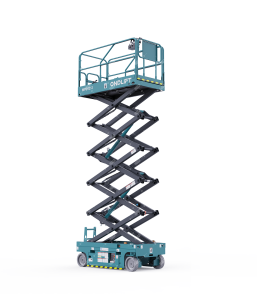

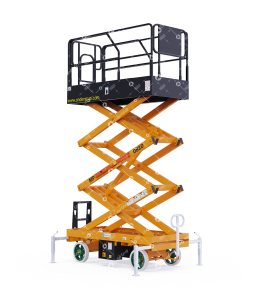

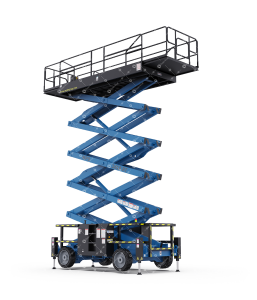

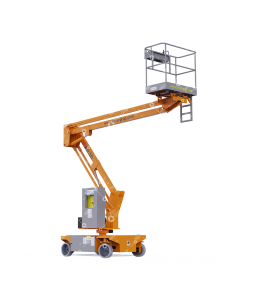

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

Onderlift is Taking Its Place at ProMat 2025!

What to Consider When Choosing a Mobile Scissor Lift Table?

What Is a Mobile Scissor Lift Table and Where Is It Used?

What to Consider When Choosing a Loading Dock Table?