Meanings and Solutions of Manlift Error Codes

Meanings and Solutions of Manlift Error Codes

Manlifts are important equipment that provide safe working opportunities at high places in various work areas. However, like every machine, manlifts may encounter malfunctions from time to time. Correct identification and resolution of these malfunctions is critical for occupational safety and operational efficiency. In this article, we will explain what manlift fault codes mean and how to troubleshoot these faults.

1. System Startup and Communication Errors

01 – System Initialization Error: This error indicates that the main control board may be faulty. As a solution, it is necessary to replace the main control card.

02 – System Communication Error: This error indicates a problem with the communication cables or other cable connections. Check communication cables and connections. If the problem persists, replace the control box or main control board.

2. Invalid Option and Key Errors

03 – Invalid Operating Mode Error: Set the correct operating mode for the machine.

12 – Power On Switch On Error: This error indicates that the trip switch wiring or switch may be stuck. Check the power switch wiring and make sure the switch is not stuck.

3. Sensor and Calibration Errors

18 – Pit Protection Error: Check whether the pothole protection skirts are open. Check pit limit switches and cables.

31 – Pressure Sensor Error: Check the sensor and its connections. Also make sure the correct mode is selected for load sensing.

32 – Tilt Sensor Error: Check the sensor and its connections. Again, make sure the correct mode is selected for load sensing.

35 – Invalid Data in ECU After Calibration: Repeat the calibration procedure accurately.

38 – Lack of Calibration When the Load Sensing Function is Active: Make sure the sensors are functional and repeat the calibration procedure.

4. Joystick and Driving Errors

42 – Left Turn Key Pressed Error at Startup: Make sure the left rotation switch is not pressed from the outside. If not, replace the joystick or control box.

43 – Right Turn Key Pressed Error at Startup: Make sure the right rotation switch is not pressed from the outside. If not, replace the joystick or control box.

46 – Joystick Trigger Pressed Error at Startup: Make sure that the joystick trigger is not pressed from the outside. If not, replace the joystick or control box.

47 – Joystick Not in Normal Position Error at Startup: Make sure the joystick is on the neutral (upright) axis. Check neutral zone parameter settings in LabView software. If the settings are correct, replace the joystick or control box.

5. Driver and Platform Errors

52 – Forward Driving Coil Error: Check coil cable and terminal connections. If there is no problem, check if the coil is open or shorted.

53 – Reverse Driving Coil Error: Check coil cable and terminal connections. If there is no problem, check if the coil is open or shorted.

54 – Platform Elevation Coil Error: Check coil cable and terminal connections. If there is no problem, check if the coil is open or shorted.

55 – Platform Descent Coil Error: Check coil cable and terminal connections. If there is no problem, check if the coil is open or shorted.

56 – Right Return Coil Error: Check coil cable and terminal connections. If there is no problem, check if the coil is open or shorted.

57 – Left Return Coil Error: Check coil cable and terminal connections. If there is no problem, check if the coil is open or shorted.

6. Common Errors and Other Problems

68 – Low Voltage Error: Check battery voltage, charge batteries if necessary. Check the battery connections and make sure the terminals are tight. Check the voltage supplied to the main control board and control box.

80 – 80% of Loading Capacity: The weight on the platform is close to the maximum load capacity. Do not load extra weight.

90 – 90% of Loading Capacity: The weight on the platform is close to the maximum load capacity. Do not load extra weight.

99 – 99% of Loading Capacity: The weight on the platform is close to the load limit. Do not load extra weight.

OL – Platform Overload Error: Remove any excess load from the platform.

LL – Preset Trend Limits Exceeded: If the machine is on an incline, move it to a flat surface. If the machine is on a level surface, check the tilt sensor and its connections.

These are the manlift error codes in general.

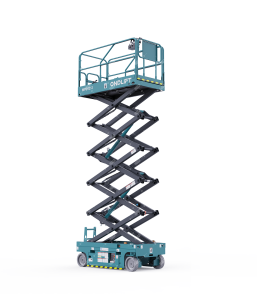

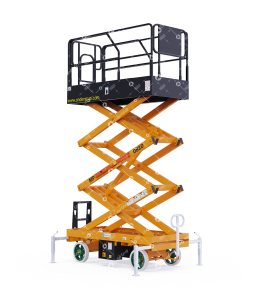

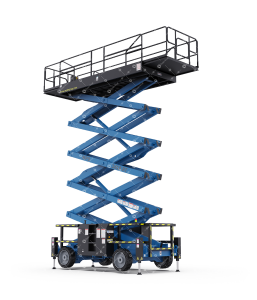

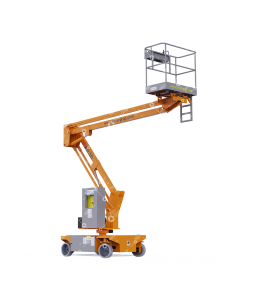

PHOTO GALLERY

Categories

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

Onderlift is Taking Its Place at ProMat 2025!

What to Consider When Choosing a Mobile Scissor Lift Table?

What Is a Mobile Scissor Lift Table and Where Is It Used?

What to Consider When Choosing a Loading Dock Table?