Uygulamalar

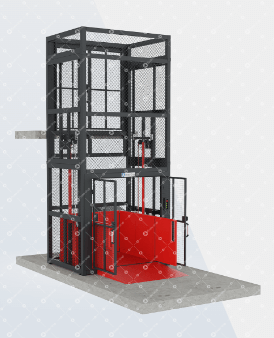

How is Freight Elevator Maintenance Performed?

Freight elevators are an indispensable tool for transporting materials in many areas, from industrial facilities to large warehouses, from shopping centers to factories. Regular maintenance is crucial for these elevators to operate efficiently and safely. Without proper maintenance, the performance of freight elevators may decline, malfunctions may occur, and this could lead to operational disruptions. Regular maintenance ensures that the elevators operate efficiently and guarantees compliance with safety standards.

You can follow the list below to perform freight elevator maintenance

- Take Safety Precautions: Before starting maintenance, cut off the elevator’s power source and hang warning signs indicating that the elevator is under maintenance.

- Prepare Tools and Equipment: Gather the necessary tools, spare parts, and maintenance materials.

- Check the Overall Condition of the Elevator: Review the general condition of the elevator, paying special attention to the motor, hydraulic system, rails, and door mechanisms.

- Perform Motor and Hydraulic System Maintenance: Ensure that the motor is functioning properly, the oil level is sufficient, and there are no leaks in the hydraulic system.

- Inspect the Rails and Cabin Mechanism: Check that the rails are straight and that the cabin mechanism is operating correctly. Lubricate the rails if necessary.

- Check the Door and Sensor Systems: Ensure that the doors are opening and closing correctly and that the sensors are functioning properly. Test the functionality of the sensors.

- Perform Lubrication and Greasing: Lubricate the moving parts of the elevator with appropriate oil and grease. Be sure to lubricate critical points such as the motor and rails.

- Inspect the Electrical System and Control Panel: Review the electrical connections, control panel, and safety systems. Check for any signs of wear, looseness, or malfunction.

- Detect and Repair Faults and Wear: Note any faults or wear detected during maintenance and repair them immediately. Replace spare parts if necessary.

- Perform Cleaning: Clean the interior and exterior surfaces of the elevator, the rails, and the cabin mechanism. Remove dust, dirt, and debris.

- Perform Functional Tests: After maintenance, test all functions of the elevator. Ensure that the doors, sensors, motor, and hydraulic system are working properly.

- Update Maintenance Records: Record all maintenance activities and detected issues in detail. These records will be an important reference for future maintenance and troubleshooting.

- Perform Final Checks and Recommission the Elevator: After all maintenance tasks are completed, recommission the elevator and perform final checks to ensure normal operation.

How Often Should Freight Elevator Maintenance Be Performed?

The frequency of maintenance for freight elevators may vary depending on the intensity of use, the weight of the loads being transported, and the environmental conditions where the elevator is located. Generally, monthly routine checks and annual detailed maintenance are recommended. During monthly checks, the general operation of the elevator is reviewed, critical parts are inspected, and minor adjustments are made if necessary. In annual maintenance, all mechanical and hydraulic systems of the elevator are thoroughly examined, necessary repairs are made, and spare parts are replaced.

Especially in hydraulic elevators, the level and condition of the hydraulic fluid should be regularly checked. A drop in fluid level may indicate a leak in the system, and this situation requires immediate intervention.

General Checklist for Freight Elevator Maintenance

When performing maintenance on a freight elevator, the following key points should be checked:

- Motor and Hydraulic System: Regularly check that the motor is working properly and that there are no leaks in the hydraulic system. Also, inspect the hydraulic fluid level to ensure it is normal and check for any changes in the color or viscosity of the fluid.

- Rails and Cabin Mechanism: Carefully inspect the rails and the cabin mechanism through which the elevator moves. Look for any signs of wear, bending, or deformation in the rails, and lubricate them if necessary. Ensure that the cabin mechanism is functioning correctly and that the doors are opening and closing safely.

- Door and Sensor Systems: Ensure that the doors are opening and closing correctly, that the sensors are functioning properly, and that there are no signs of malfunction. Door sensors are a critical safety system that prevents the door from closing when there is an obstruction in front of the elevator door.

Things to Consider During Freight Elevator Maintenance

Freight elevators carry large and heavy loads, so it is essential to take safety precautions meticulously during maintenance. Ensure that the elevator is entirely deactivated and the power is cut off during maintenance. Additionally, the spare parts used during maintenance must be original and have the appropriate certifications. Using aftermarket parts can negatively affect the elevator’s performance and pose safety risks.

The oils, greases, and other materials used during elevator maintenance should also be suitable for the elevator type and operating conditions. Using inappropriate materials can lead to wear and malfunctions in the mechanical components of the elevator.

Common Maintenance Issues in Freight Elevators

One of the most common maintenance issues in freight elevators is motor failure. The motor is considered the brain of the elevator, and any motor malfunction can cause the elevator to come to a complete stop. Hydraulic fluid leaks are also a frequent issue. Leaks in the hydraulic system weaken the elevator’s lifting capacity and can lead to more significant problems over time. Door mechanism failures are another common problem in freight elevators. Improperly closing doors create both a safety hazard and hinder the elevator’s efficient operation.

Tips for Prolonging the Life of Freight Elevators

To ensure that your freight elevator has a long service life, consider the following tips:

- Regular Maintenance: Regular maintenance is essential to prevent malfunctions and ensure the elevator operates efficiently.

- Proper Usage: Transporting loads that are within the elevator’s capacity prevents excessive strain on the elevator and, consequently, the formation of malfunctions.

- Timely Repairs: If you notice any issues, addressing them promptly extends the elevator’s life and prevents more significant problems from developing.

By following the Önderlift blog, you can gain more knowledge about material handling machines.

Categories

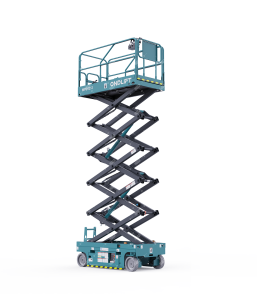

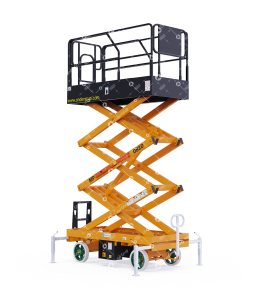

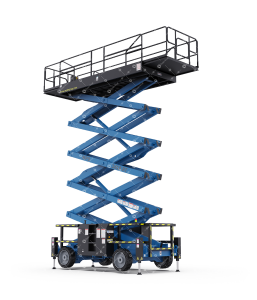

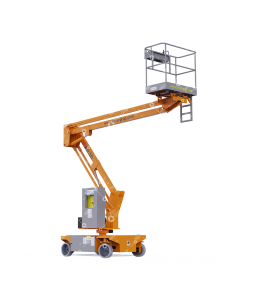

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

The Most Useful Accessories for Load Platforms and Selection Guide

How Can You Improve Workplace Safety with Load Platform Accessories?

Advantages of Hydraulic Lift Platforms

Safe Usage Procedures for Load Platforms

Proper Installation and Maintenance Steps for Load Platforms