Uygulamalar

The Role of Lifts in Occupational Safety Applications

Lifts are of great importance in occupational safety applications. Lifts, especially used in industrial enterprises, building construction and similar areas, play a critical role in both increasing work efficiency and ensuring the safety of employees.

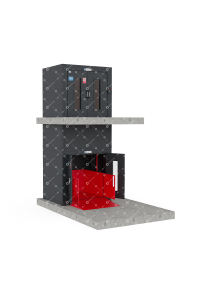

Safe Cargo Transport: While lifts are used to transport heavy loads, they provide safe transportation when used correctly. The safety of lifts used to carry materials to higher floors, especially in large industrial facilities or construction sites, is at the forefront. This reduces the risk of workers falling or getting injured while handling materials.

Accessibility: Lifts make access to high points easier. This allows workers to safely access high points during maintenance work, repairs or construction processes. Compared to other access methods such as stairs, lifts are a safer and more efficient option.

Training and Certification: Safe use of lifts should be supported by training and certification programs provided to workers. It is important that workers learn to use lifts correctly and work safely. This helps prevent accidents and injuries.

Periodic Maintenance and Control: Regular maintenance and periodic checks of lifts are important to ensure their safe operation. When any malfunction or security vulnerability is detected, the problem must be resolved immediately. Especially in industrial environments, regular inspection and maintenance of lifts helps meet occupational safety standards.

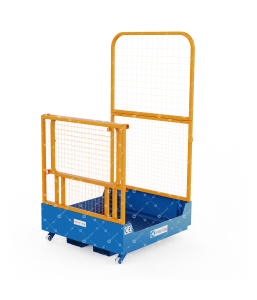

Safety Equipment: It is important to provide the safety equipment required for the safety of the lifts. This equipment includes items such as emergency stop buttons, overload sensors, safety cages or guardrails. Regular checking and maintenance of this equipment increases the safety of the lifts.

To summarize, lifts play an important role in occupational safety applications. When used correctly, they become an indispensable tool to ensure the safety of workers and increase work efficiency. Therefore, businesses should take the necessary precautions for the safe use of lifts and train and inform their employees on this subject.

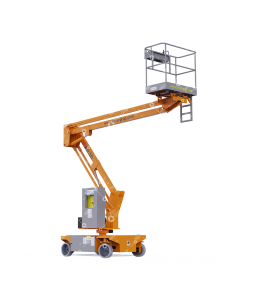

Occupational Safety in Manlift Use

Manlifts are important equipment that provides access to high points and facilitates the transportation and working processes of workers. However, the use of these devices should be handled carefully in terms of occupational safety.

First of all, for occupational safety, it is important to use manlifts correctly and provide necessary training to workers. Workers must learn to operate manlifts safely and know how to react in any emergency. It is also vital that manlifts’ safety equipment is regularly checked and maintained. This equipment includes emergency stop systems, guardrails, and overload sensors. These are necessary to ensure the safety of workers.

Secondly, workers must follow certain rules when using manlifts. For example, it is important not to exceed the maximum payload and to pay attention to height restrictions. Additionally, workers are required to stay on the platform and maintain their balance while the manlift moves. Violation of these rules can cause serious accidents. Therefore, in terms of occupational safety, these rules must be followed in a disciplined manner when using manlifts.

Things to Consider When Using Manlift

Before learning what to consider when using a manlift, you need to know what you need to know when buying a manlift and the answer to the question of how manlifts work. Manlifts are important equipment that provides access to high points and increases the working efficiency of workers. However, certain precautions must be taken for the safe use of these devices.

First, when using a manlift, it is critical that workers are trained and know how to use the device properly. Workers must learn how to operate the manlift, know emergency procedures and understand how to use safety equipment. Training is vital to preventing accidents and ensuring worker safety.

Secondly, workers must follow certain rules when using a manlift. These include not exceeding the maximum carrying capacity, not keeping unnecessary items on the platform, and maintaining the balance of the platform. Additionally, it is important to stay on the platform and be careful while the manlift is in motion. Violation of these rules may result in serious accidents and injuries.

Finally, manlifts must be maintained regularly and periodic checks must be carried out. Timely replacement of worn or damaged parts is important for safety. It is also important that workers check the device before using the manlift and report any problems. In this way, a safe working environment can be ensured and help prevent accidents.

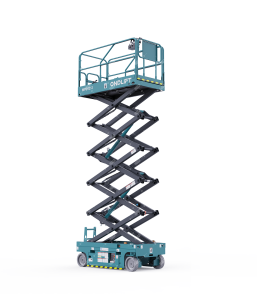

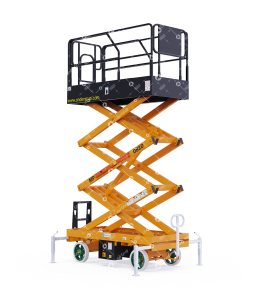

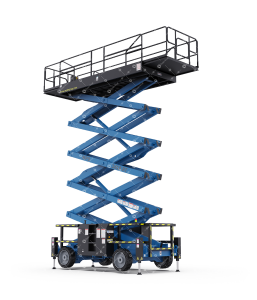

PHOTO GALLERY

Categories

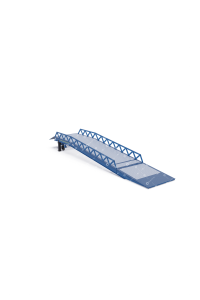

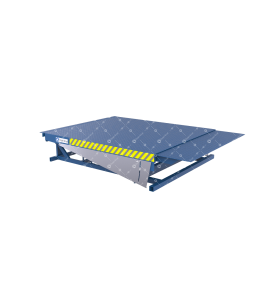

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

Onderlift is Taking Its Place at ProMat 2025!

What to Consider When Choosing a Mobile Scissor Lift Table?

What Is a Mobile Scissor Lift Table and Where Is It Used?

What to Consider When Choosing a Loading Dock Table?