Uygulamalar

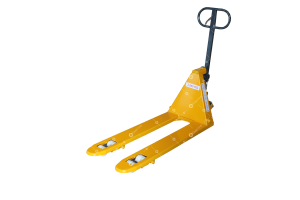

What is a Pallet Jack?

What is a Pallet Jack?

What is a pallet jack? Pallet jacks are vehicles designed to facilitate the transportation of loads and are widely used in various areas such as warehouses, factories, and commercial centers. In this article, we will thoroughly examine what pallet jacks are, how they work, and in which areas they are used.

What is the Definition of a Pallet Jack? And Where is it Used?

Pallet jacks are manual or motorized vehicles used to easily transport palletized loads. They are commonly used in places like warehouses, logistics centers, production facilities, supermarkets, and distribution centers. Pallet jacks allow for the quick and safe transport of loads, reducing labor and increasing operational efficiency.

What Are the Types of Pallet Jacks?

Pallet jacks are divided into two types based on their intended use: manual and motorized (electric) models.

- Manual Pallet Jacks: These models, powered by hand, are generally more cost-effective and require less maintenance. They are preferred in small warehouses, narrow spaces, or for short-distance transport operations.

- Electric Pallet Jacks: Powered by a battery, these models allow for the faster and easier transport of heavy loads. They are especially used in large warehouses, areas with heavy workloads, and for long-distance transportation needs.

What is a Hand Pallet Jack?

Hand pallet jacks are manual pallet jacks ideal for transporting smaller and lighter loads. They are typically used in small warehouses or narrow spaces. The advantages of hand pallet jacks include low cost, ease of use, and minimal maintenance. These features make them one of the most preferred tools by businesses.

What Are the Technical Specifications and Capacities of Pallet Jacks?

Pallet jacks come with various technical specifications and capacities. To choose the most suitable pallet jack for your business needs, it is important to consider these features:

- Load Capacity: Pallet jacks generally have load capacities ranging from 2 to 5 tons. Choosing based on load capacity is critical for both safety and efficiency.

- Fork Length and Width: There are fork lengths and widths that vary according to different pallet sizes. The fork length should be suitable for the dimensions of the pallets; otherwise, balance issues may arise during transportation.

What Should You Consider When Choosing a Pallet Jack?

Choosing the right pallet jack increases your business’s efficiency and reduces operational costs. Here are some important factors to consider when selecting a pallet jack:

- Model Selection According to Needs: Pallet jack selection should be made by considering factors such as the amount of load, frequency of use, and the width of the workspace. For example, an electric pallet jack should be preferred in a warehouse that requires frequent and heavy load transportation.

- Maintenance and Service Requirements: Regular maintenance of pallet jacks is necessary for long-term use and safe operation. When making a selection, you should also consider the maintenance and service requirements of the chosen model.

Conclusion

Pallet jacks are essential tools that facilitate material handling, saving labor and time. Choosing the right pallet jack will increase the efficiency of your business and reduce operational costs. As Önder Lift, we provide the most suitable pallet jack solutions for your needs, helping you make your operations more efficient.

Categories

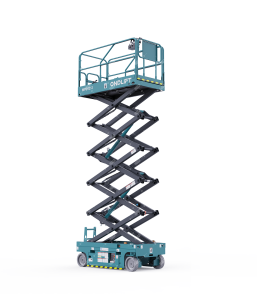

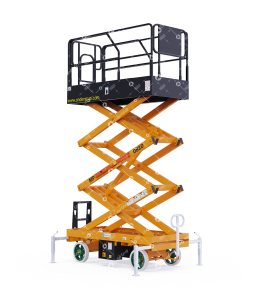

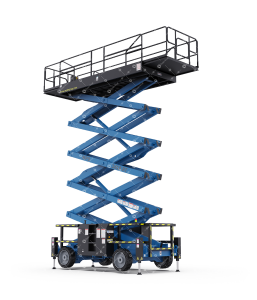

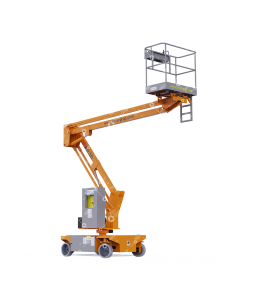

Single Scissor Lift Table Double Scissor Lift Table High Scissor Lift Table Stainless Steel Single Scissor Lift Table Galvanized Lift Table Car Lift Table Disabled Lift Disabled Lift Low Profile Disabled Lift Mobile Disabled Lift Column Type Disabled Lift Ball Screw Scissor Lift Table U / Low Profile Lift Tables Super Low Profile Scissor Lift Table U Type Low Profile Lift Table Low Profile Lift Table Stainless Steel Low Profile Lift Table Stainless Steel U Type Low Profile Lift Table Mobile Scissor Lift Table Loading Dock Table Tandem Type Scissor Lift Lift Tables Accessories Aerial Work Platform Scissor Lift Push By Hand Scissor Lift Rough Terrain Scissor Lift Trailer Scissor Lift Goods Lift Loading RampsUsage Areas

Aerospace Agriculture Automotive Defense Industry Education Energy Entertainment Food & Pharmaceutical Heavy Equipment logistic Logistics Manlift Manufactoring Manufacturing Manufacturing metal working Metal Working Retail WoodworkingRecently Added

Onderlift is Taking Its Place at ProMat 2025!

What to Consider When Choosing a Mobile Scissor Lift Table?

What Is a Mobile Scissor Lift Table and Where Is It Used?

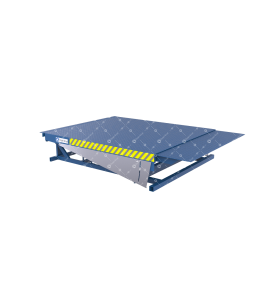

What to Consider When Choosing a Loading Dock Table?